Here are your bioenergy options:

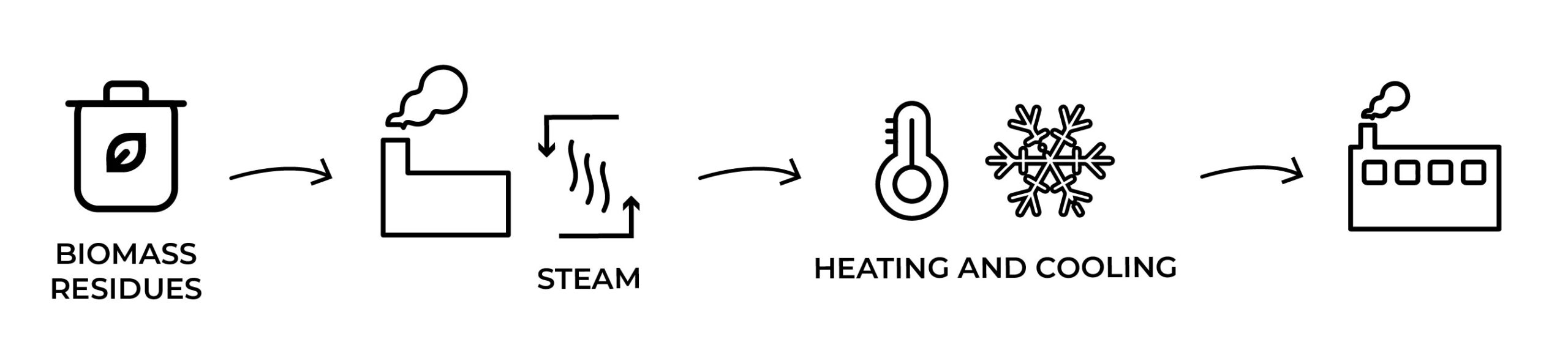

When the pyrethrum plant is processed for its natural insecticide (the chemical pyrethrin), the leftover parts of the plant are turned into briquettes, able to be burned as a biofuel. Meat processor Greenham Tasmania is burning pyrethrum briquettes to power the main steam boiler at its Smithton export abattoir, accounting for up to 30 per cent of its energy demands. The transition involved a $1.3m investment and several years of refinement.

https://www.botanicalresources.com/our-pyrethrins/sustainability

Check the Biomass Producer Website for more Bioenergy case studies.

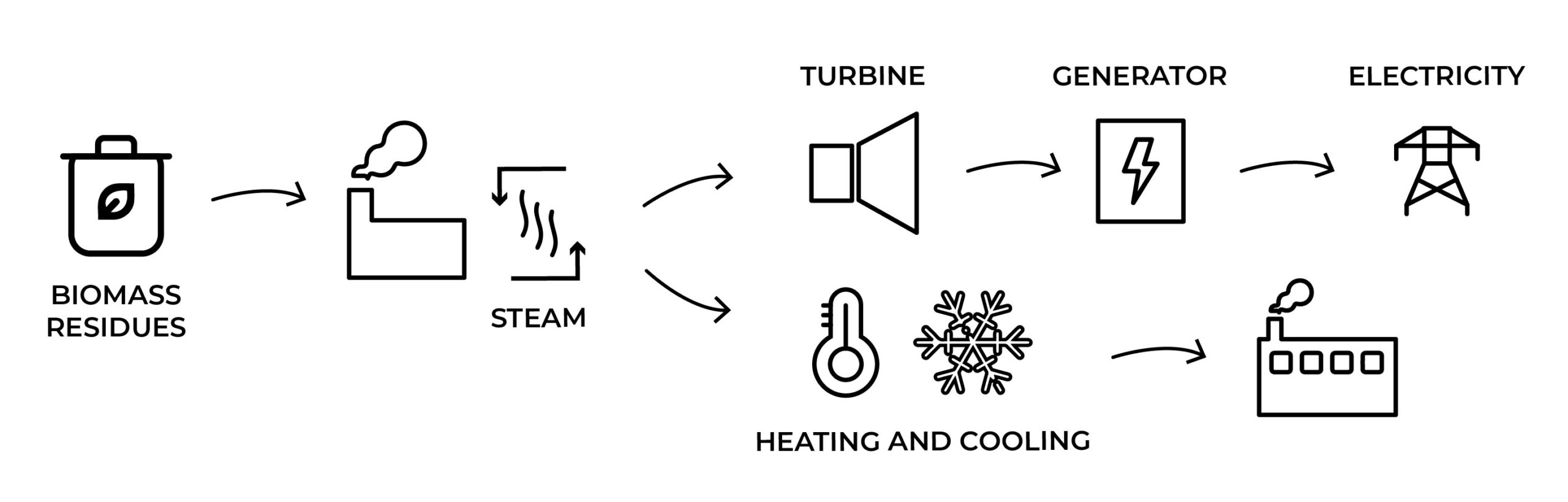

Cape Byron Power, operated by Cape Byron Management, consists of two 30 MW biomass fired power stations, on the NSW north coast. Together, these form one of the largest renewable base load generators in Australia. The electricity is predominantly produced from sugar cane milling waste, along with certain types of wood residues and energy crops, commonly referred to as ‘biomass’ fuel. Cape Byron Management, led by a highly experienced board of directors and management team, is at the forefront of sustainable biomass practices and has a commitment to continuous improvement and innovation; driving fuel procurement according to defined principles of best practice benchmarks. Cape Byron Management Team are leaders in responsible and sustainable biomass power generation providing carbon neutral, cost effective and reliable renewable power now, and into the future. Cape Byron Management uses sustainably sourced biomass fuels which are low carbon, cost effective and renewable.

https://www.capebyronpower.com/

Check the Biomass Producer Website for more Bioenergy case studies.

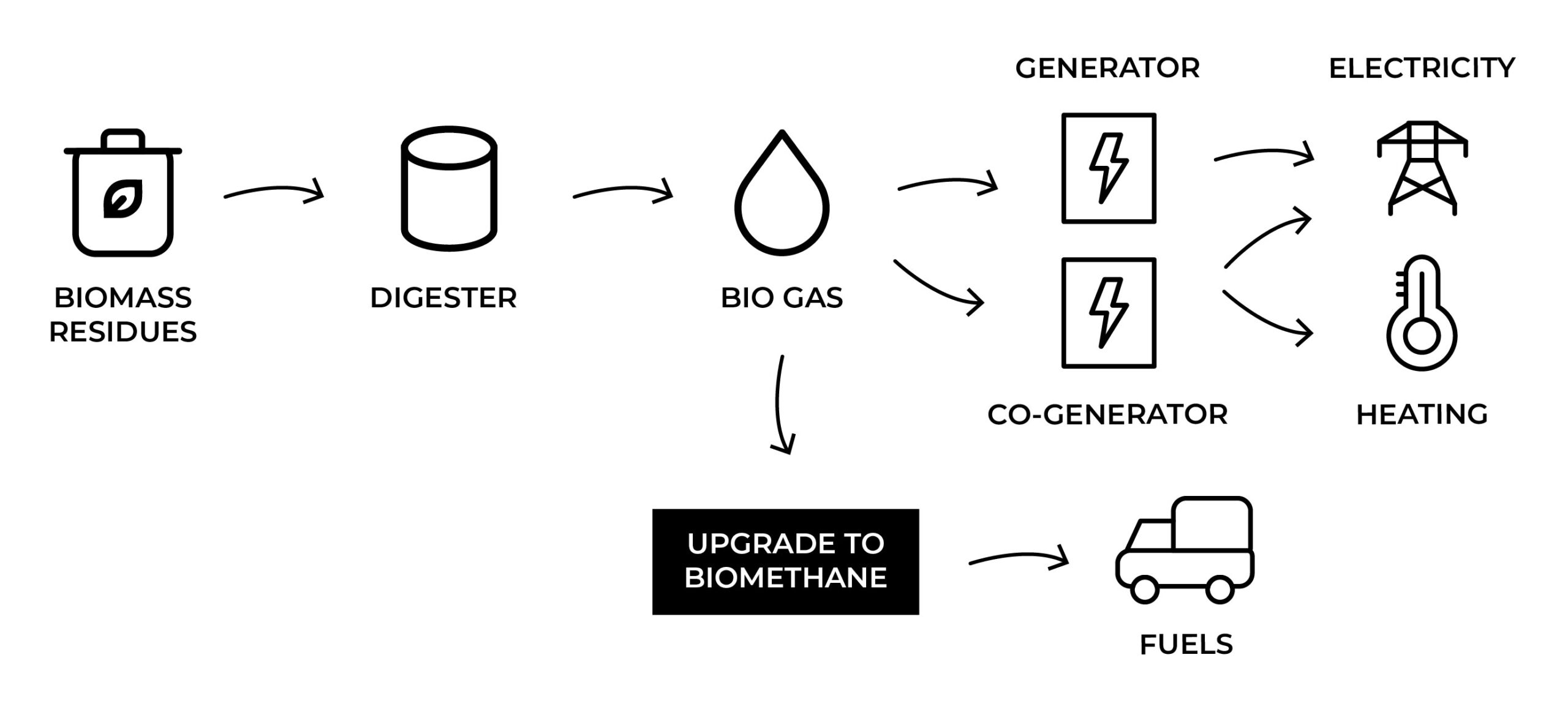

JBS Australia, the country’s largest meat processor and exporter, is capturing and using biogas at its Dinmore, Queensland facility to reduce dependence on grid-connected natural gas by about 50 per cent. CEFC strategic alliance partner Wiley constructed and designed the biogas and water treatment plant and earned the Queensland Master Builders Association award for Innovation in Environmental Management Construction for its work with JBS. JBS Australia employs about 2,000 staff at its Dinmore processing facility where it installed new pre-treatment equipment and covered anaerobic lagoons to capture the biogas generated at the site. The facility has reduced its carbon emissions by 89 per cent and is saving more than $1 million a year on natural gas costs.

http://www.wiley.com.au/projects/biogas-recovery-project-gives-jbs-environmental-and-financial-edge/

Check the Biomass Producer Website for more Bioenergy case studies.

Do you need assistance?

Our consultants can help with your next bioenergy project! Click the arrow for contact details